Introduction of the New LM920 Compact Wheel Loader

LM920 Compact Wheel Loader Introduction

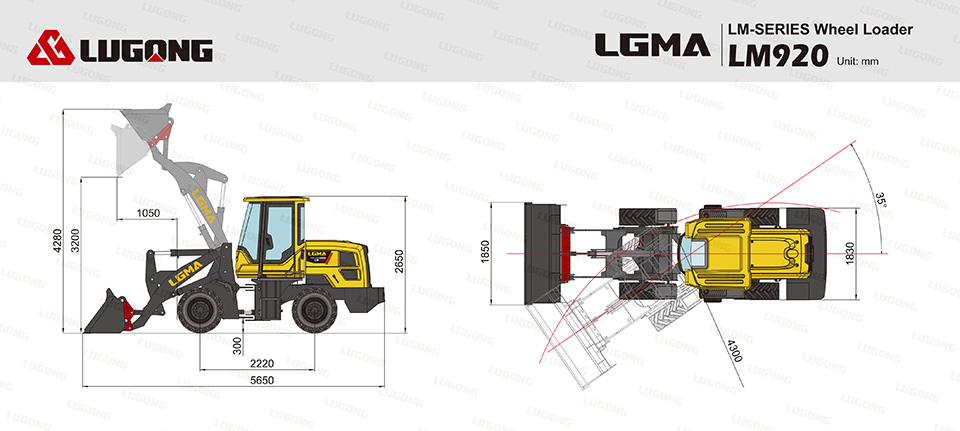

The working weight of LM920 compact wheel loader is 1600kg, bucket capacity is 0.7m³, unloading height is 3200mm, size 5670mm*2680mm*1800mm. LM920 is a brand new design, based on the original wheel loader, it has made more than 40 technological innovations and upgraded components. The cab structure, torque converter and body body painting color matching are all significantly improved, which further enhances the operation convenience and efficiency of the machine, reduces energy consumption and maintenance costs, and creates greater economic benefits for users.

LM920 Compact Wheel Loader Structure

LM920 Compact Wheel Loader Features

Integrated Gearbox

The LM920 wheel loader is an integral gearbox. Compared with a split transmission, th.connection point with the frame has been reduced from epoints to 4 points, resulting in less resonance and lower noise during loader start-up and operation.

Multi-stage Filtration System

Adopting dual air filter inlet and cyclone dust pre filter, it can effectively filter large particles. Perform secondary fitration on the oil filter again(with low usage cost). Paper filter 1634 precision filtration. The entire filtration system greatly extends maintenance and extends the service life of the engine. This filtering system is very suitable for dusty and harsh working environments.

Electric Control Armrest Box

The standard electronic control armrest box design conforms to ergonomics and is equipped with an adiustable lifting plate.providing a higher and more comfortable operating experience for the driver. By adding electronic gear shifting operations, it is possible to achieve forward and backward movement with onehand, lifting and folding actions, making gear shifting operations simpler, more convenient, and flexible.

Control System

The electronic control shifting technology is selected, and the torgue converter shifting valve adopts electromagnetic shifting control technology. The puling force of the electromagnet is 15 times higher than that of the solenoid valve, and the shifting stroke of the valve stem is extended. The shifting oil passage is widened from 6mm to 16mm, effectively solving the problem of valve stem jamming.By adopting advanced programmable logic controller (PLC)technology, precise automation controhas been achieved. The system has self diagnostic function,which can monitor the operation status of equipment in realtime, detect and warn potential problems in a timely manner and ensure the stability and reliability of the equipment.

Adjustable instrument Panel

The standard configuration includes an adjustable instrumentpanel, and the sub high low speed and gear lever have beenchanged from the left side of the steering wheel to the left andright sides of the seat, greatly increasing the driver’s legroomand operating space.

Rear Counterweight

The rear counterweight is a five hole traction rear counterweight, which strengthens the traction material, increases the traction points (upgraded from 1 point to 5 points),and enhances the traction force. Add protective covers to the tailights of the rear hood to avoid collisions, provide higher protection, and extend the service life of the lamps.